Hadrian X and the FBR team on an outdoor build. Courtesy FBR. Brick is one of the oldest building materials, dating back to 7000 BC for sun-hardened varieties and 3500 BC for the first kiln-fired blocks. It’s also among the most versatile, used for modern “abstract menorah ” shapes and stunning arches . Even the method of laying bricks—spreading mortar, positioning a brick, and smoothing out excess mortar with a trowel—has remained the same for millennia.

Now, one company aims to augment this thousand-year-old tradition through technology. Australian-based construction-technology firm FBR (formerly Fastbrick Robotics) has developed Hadrian X , a bricklaying robot (named after the wall-building Roman emperor ) that can do its work without any human intervention. Hadrian X can work without human intervention. Courtesy FBR. This technology could provide wide-reaching benefits, including addressing housing shortages around the world. “There aren’t enough people to build houses fast enough,” says Steve Pierz, chief innovation officer at FBR. “We need to automate the process through mass construction, and this is one of the ways it can be done.” Pierz also sees an opportunity to rebuild after natural disasters strike. “I envision fleets of these robots putting up housing structures quickly in disaster areas,” he says.

Hadrian X’s precision could also improve efficiency, resulting in houses that can be built faster and cost less than traditional methods. And Hadrian X promotes a lean-construction approach in which productivity increases and waste decreases. “We take a single source of data and from there, we’ll know the number of blocks and the amount of adhesive required given the lay pattern,” says Simon Amos, director of construction technologies at FBR. “So you’re fully informed up front what waste, if any, there will be.”

Hadrian X looks like a typical truck-mounted crane, but it’s assembled from complex components: a control system, a block-delivery system, and a dynamic stabilization system. Putting these systems together brings Hadrian X to life. Once blocks are loaded onto the machine, it identifies each one and decides where it goes. The machine can also cut blocks into quarters, halves, or three-quarters when needed and store them for later use. These blocks are then fed into a boom-transport system and conveyed to a layhead, which lays out the blocks based on logic and the pattern programmed into the machine.

“The layhead is where the magic happens,” Pierz says. “So even with wind blowing and vibration shaking the entire boom, it’s holding that block, compensating hundreds of times a second to keep that block at the precise location.” A close-up view of Hadrian X laying bricks. Courtesy FBR. The Hadrian X robot has been more than a decade in the making. The initial idea for a dynamically stabilized robot was conceived in 1994, but it wasn’t until 2005 that FBR founder and Chief Technical Officer Mark Pivac created the first prototype. When the global financial crisis hit in 2008, production stalled for Hadrian X’s predecessor, Hadrian 105. The project resumed in 2014 in the midst of a stronger economy, a boom in construction, and a labor shortage for bricklayers and masons. By 2016, development began on the next iteration, Hadrian X.

The robot’s control system is the “brains” behind it. Using Cartesian coordinates and parametric design , FBR’s proprietary software transforms a wall structure modeled in CAD into brick metadata, with every brick and its corresponding coordinates known. The software then uses the metadata to populate the bricks into a particular nesting pattern and, with the help of an algorithm, determine how to lay out the bricks according to the pattern and other parameters such as the size of the robot’s layhead and how it grips the blocks.

For Hadrian X’s wall system, FBR designed its own blocks and block geometry. “The notion of a block is based on a human handling a brick and laying it at a certain rate,” Amos says. “We changed that to suit a robot.” Hadrian X’s blocks have been optimized to ensure wall thickness is consistent. They’re 12 times larger than a standard brick to maximize lay rate; Hadrian X is capable of laying one block every 45 to 55 seconds. FBR uses a special adhesive that bonds faster and holds stronger than traditional mortar.

For the actual operating mechanics of the machine, Pivac used his background in aeronautics, mechanical engineering, robotics, and mathematics to develop a patented Dynamic Stabilization Technology ( DST ). DST enables accurate positioning of blocks over large distances in a 3D space, counteracting the effects of wind, vibration, and other environmental factors to keep blocks at their precise location. This stability allows Hadrian X to be mounted onto other bases—including barges, boats, cranes, and tracks—and to be used for bricklaying in other sites. FBR employee Cosimo Santella performs dynamic stability testing. Courtesy FBR. “The challenge is making sure all these systems come together—that they’re highly coordinated, there’s strong choreography between all the modules within the robot, and that we can clearly manage all the environmental issues that sit around a dirty, dangerous construction site,” Amos says.

To overcome these challenges, the components of Hadrian X were rigorously tested, with each testing phase bringing lessons and improvements. Hadrian X’s milestone build was done internally in November 2018, completing a 180-square-meter home within three days. The next step involved outdoor testing during the peak of Australia’s scorching summer in February 2019.

“We did an outside build to collect data and try to understand environmental influences as we brought our robot into high temperatures,” Amos says. “A lot of this was about really challenging the robot, putting it out into a fairly aggressive, hostile wind and temperature curve, and seeing what it did.” Mike Pivac (left) and Mark Pivac inspect equipment. Courtesy FBR. FBR is already preparing for the global future of Hadrian X. The company signed an agreement with GP Vivienda—the housing division of Grupo GP, one of Mexico’s largest construction companies—to explore pilot programs in the country. The firm also signed a memorandum of understanding with the Kingdom of Saudi Arabia to discuss a project building 50,000 new homes. Another partnership is in place with Wienerberger, an Austrian-based clay-block manufacturer, to create optimized clay blocks for Hadrian X and plan a pilot project in Europe.

Back home in Australia, FBR has partnered with Brickworks, a major supplier of building products, to deliver “Wall as a Service” across the country. Through Wall as a Service, Brickworks will supply special concrete masonry blocks for FBR’s bricklaying robot to build the walls, focusing on residential projects.

Pierz believes that Hadrian X has the potential to change the construction industry. “Disruption only comes when you look at your industry from a completely different angle,” he says. “You have to be willing to try and experiment with new technologies or you’ll be left behind.”

This Bricklaying Robot Is Changing the Future of Construction

ED cheers innovation hubs

Click here to view original web page at www.sundaymail.co.zw

Farirai Machivenyika

Senior Reporter

The Zimbabwe Manpower Development Fund (Zimdef) has been commended for funding innovation hubs that have been established at several universities across the country.

Speaking after touring exhibition stands at Zanu-PF’s 18th National People’s Conference, which ended yesterday at Goromonzi High School, President Emmerson Mnangagwa said the parastatal’s focus on funding innovation and research was the right way to go.

The innovation hubs were established to enhance research and support the country’s modernisation and industrialisation drive.

“We are so happy the thrust of the exhibitions is agricultural and also in the area of innovations,” he said.

“We are impressed by the current thrust of Zimdef, which is supporting most of the innovation hubs at universities. This is now changed from the past history of Zimdef, where funds were used to buy bicycles. Now the funds are being used to fund proper innovations and inventions at universities.”

His remarks follow the alleged abuse of Zimdef funds by fugitive former Higher and Tertiary Education Minister Professor Jonathan Moyo after he diverted over US$270 000 to buy bicycles for traditional leaders in Tsholotsho, Matabeleland North.

The President also commended seed companies for venturing into manufacturing of small grains seed.

“Generally, you can also see the thrust by seed companies, they have normal seed varieties, but traditional seed varieties are now being exhibited.

“In the past we were only exposed to maize, soya(bean) and wheat, but now you can also see rukweza (finger millet) mhunga (sorghum), mapfunde, so we are so grateful,” President Mnangagwa added.

He also expressed satisfaction with operations of Silo Foods Industries, a subsidiary of GMB tasked with providing cheap basic commodities to vulnerable households, especially in rural areas.

“We are tending to the most disadvantaged of the communities and we have seen what the Silo shops are doing, where poor families are being provided for at very reasonable prices.”

“It now has 84 shops countrywide available at GMB depots and other satellite shops

“The company’s product range include mealie-meal, rice and sugar beans, salt, samp, bran, peanut butter, kapenta and flour, among others.”

Indian investors flock to Zim

Click here to view original web page at www.sundaymail.co.zw

Golden Sibanda

Senior Business Reporter

THE new dispensation’s rallying call, that Zimbabwe is open for business, has roused the interest of Indian investors amid indications that investment proposals from the Asian economic giant are growing at a fast pace.

Investment registrations by Indian investors appeared to take a plunge in 2016, after proposed investments dropped from 13 to seven, but shot up to 37 by the end of last year.

From January 2019 to date, registrations for proposed investments in Zimbabwe have hit 39, with expectations high that by the end of the current year, investment proposals from India will reach 50.

Last month, Indian Ambassador to Zimbabwe Rungsung Masakui noted that since January, registrations with investment authorities had reached 25. He was confident the number will double by year end.

True to that forecast, proposed investments from the Asian economic giant have already risen to 39, with most investors targeting agriculture, mining, SMEs, education and manufacturing.

“In 2016, there were 13 registrations with the Zimbabwe Investments Authority, which came down to seven in 2017.

“In 2018, registrations shot up to 37. As I speak, registrations are now standing at 39,” he said.

Since assuming power in November 2017, President Mnangagwa has declared that Zimbabwe is open for business. ln addition, Zimbabwe is targeting to achieve middle income status by 2030.

An improving investment climate saw Zimbabwe’s Foreign Direct Investment (FDI) inflows more than doubling from $349 million in 2017 to $745 million in 2018.

This tallies with the World Bank’s observations this year. According to the bank, Zimbabwe was among 2018’s top 20 improvers with regards to ease of doing business, alongside other African countries that included Kenya, Djibouti, Nigeria and Togo.

President Mnangagwa has pledged that Government will continue to create an enabling environment for the convenience of conducting business in Zimbabwe. This includes reduced costs of doing business and ensuring the country’s safety, attractiveness and competitiveness as an investment destination.

Ambassador Masakui said Indian firms that are already operating in Zimbabwe were also expanding their operations despite the challenging economic conditions.

Varun Beverages, one of the biggest firms on India’s soft drinks market, last week commissioned three production lines in Zimbabwe. This tripled the company’s soft drinks’ production capacity to about 35 million cans and bottles per month.

The company’s billionaire founder, Mr Ravi Jaipuria, was in the country to witness the commissioning. He commended Government for extending the requisite support.

Mr Jaipuria also expressed gratitude as Zimbabwe had embraced his firm’s products Mirinda, Pepsi Cola, Mountain Dew and Sting energy drink, which are all bottled under franchise from PepsiCo International.

The government of India already enjoys cordial socio-economic and political relations with the Government of Zimbabwe, which has seen it committing to extend US$310 million for the upgrade of Hwange Power Station.

India has also facilitated a US$110 million line of credit for the repowering of Bulawayo Power Station. The tender process for the project is already underway in India while another US$45 million will go into the Deka Pump Station upgrade.

Deka Pump Station is critical in the operation of Hwange Power Station, Zimbabwe’s biggest base load power plant.

The pump pushes water to the plant for use in its cooling towers through a 42-kilometre pipeline.

Mr Masakui said while the Indian investors’ interest continues to grow, Zimbabwe needs to do more to further improve the ease and cost of doing business.

Big Indian investors already operating in Zimbabwe include edible oil producers Cangrow Trading and Surface Wilmar, Pure Oil Industries, Varun Beverages and paint maker Splash Paints, which recently opened a new plastic recycling company.

Vladimir Putin, Xi Jinping and Elizabeth II congratulate Kazakhstan on Independence Day

Click here to view original web page at www.inform.kz

NUR-SULTAN. KAZINFORM – Global leaders continue to send their greetings on the occasion of the upcoming Independence Day of the Republic of Kazakhstan to the Head of State Kassym-Jomart Tokayev, Kazinform has learnt from the press service of Akorda. Kazakhstan’s only lowcoster implements its first int’l flight Kassym-Jomart Tokayev’s portrait appears on newsstands in France Kazakhstan Independence Day celebrated in Israel Weather deterioration alert issued for 5 regions

President of the Russian Federation Vladimir Putin extended his congratulations to the Head of State Kassym-Jomart Tokayev and the people of Kazakhstan.

«The successes achieved by your country in the socio-economic, scientific-technical and many other fields are well known. Kazakhstan rightfully enjoys high prestige on the world stage, plays a constructive role in resolving pressing issues of the regional and international agenda. Relations between our states are dynamically developing in the spirit of strategic partnership and alliance. Bilateral cooperation in various areas, as well as coordination of efforts within the framework of the Eurasian integration processes give good pay-offs.» Vladimir Putin wishes the President of Kazakhstan good health and success, and the citizens of the country – happiness and prosperity.

President of the People’s Republic of China Xi Jinping sent Kassym-Jomart Tokayev congratulations on behalf of the Government and people of China, as well as on his own behalf on the occasion of the 28th anniversary of the Independence of Kazakhstan. «I attach great importance to the development of Sino-Kazakh relations and I am ready to make joint efforts with you to strengthen mutual support and fruitfully advance the joint implementation of the One Belt – One Road project for the benefit of our countries and peoples,» the congratulatory message reads. Xi Jinping concludes his congratulations with the wishes of prosperity and strength to Kazakhstan.

Queen Elizabeth II of Great Britain congratulated President Kassym-Jomart Tokayev on the Independence Day of Kazakhstan. «Your Excellency, I am sincerely congratulating you on the occasion of the national holiday. May I wish the people of Kazakhstan well-being and prosperity,» the telegram says.

«I sincerely congratulate you and the friendly people of Kazakhstan on the Independence Day. May I wish you, Your Excellency, good health, happiness and success, well-being and prosperity to your people.» President of the United Arab Emirates Khalifa bin Zayed Al Nahyan wrote in his congratulatory message.

The President of the Republic of Uzbekistan Shavkat Mirziyoyev, on his own behalf and on behalf of the Uzbek people congratulated Kazakh President Kassym-Jomart Tokayev on the national holiday. «We are sincerely glad for the impressive successes of fraternal Kazakhstan in socio-political and socio-economic development, the steady growth of the country’s authority in the international arena. Today the Uzbek-Kazakh relations have achieved a high level of trust and mutual understanding,» the telegram said.

President of Kazakhstan received a message from his Kyrgyz counterpart. «I express full confidence that the relations of strategic partnership, friendship, alliance and good neighborliness between the Kyrgyz Republic and the Republic of Kazakhstan will continue to strengthen».

Welcoming telegrams in connection with the Independence Day of Kazakhstan were also sent by the President of Tajikistan Emomali Rahmon, President of Turkmenistan Gurbanguly Berdimuhamedov and President of Azerbaijan Ilham Aliyev.

President of Ukraine Vladimir Zelensky in his congratulation noted that the Republic of Kazakhstan has become a regional leader politics, economy and security. He added that our country has strengthened its authority in the international arena. «May I wish you, Your Excellency, good health and vitality, and peace, prosperity and welfare to the friendly people of Kazakhstan.»

«Friendly Korean-Kazakh relations are developing steadily thanks to close cooperation in various fields. In particular, I’m glad that the two countries came closer to each other through active high-level collaboration,» President of the Republic of Korea Moon Jae-in emphasized in his congratulatory message.

The King of the Netherlands Willem-Alexander, the King of Malaysia Al-Sultan Abdullah Ri’ayatuddin Al-Mustafa Billah Shah, the King of Belgium Philippe, the King of Sweden Carl Gustaf, the President of the Islamic Republic of Afghanistan Mohammad Ashraf Ghani have also sent their congratulations to Kassym-Jomart Tokayev on the occasion of the 28th anniversary of Kazakhstan’s Independence.

President of Kazakhstan Kassym-Jomart Tokayev also received congratulatory messages from the

President of the Czech Republic Miloš Zeman, President of Hungary János Áder, Thailand’s Prime Minister Prayuth Chan-ocha, President of Croatia Kolinda Grabar-Kitarović, President of Bulgaria Rumen Radev, President of Lebanese Republic Michel Aoun, President of the Republic of Latvia Egils Levits, President of the Republic of Iraq Barham Salih, President of the Hellenic Republic Prokopios Pavlopoulos, Governor-General of Canada Julie Payette, Crown Prince of Abu Dhabi Mohammed bin Zayed Al Nahyan, Chairman of the CIS Executive Committee – Executive Secretary Sergey Lebedev, Secretary General of the Organization of Islamic Cooperation Dr. Yousef bin Ahmed Al-Othaimeen, Vice President of the United Arab Emirates, Prime Minister, Ruler of the Emirate of Dubai Sheikh Mohammed bin Rashid Al Maktoum, Acting Secretary General of the Collective Security Treaty Valery Semerikov.

фото: фото: azh.kz

Springfield makes billion-barrel find off Ghana

Click here to view original web page at www.energyvoice.com

Ghana’s Springfield Exploration and Production has found oil in two areas at its Afina-1 well on its West Cape Three Points (WCTP) Block 2, offshore Ghana.

The company has said it believes there are 1.5 billion barrels of oil in place, more than double its previous number, and added 700 billion cubic feet (19.8 billion cubic metres) of gas.

“This is great news for Springfield, Ghana and Africa. We are excited about the discovery as it ties into our vision of becoming a leading African upstream player with a global focus,” said Springfield E&P’s CEO Kevin Okyere. This for us means increased opportunities to impact the lives of our people positively with the resources.

The well found 65 gross metres of oil pay, of which 50 metres was net, in Cenomanian sandstones, with another 10 metres of hydrocarbon-bearing sands in Turonian-age sands. The well was drilled in 1,030 metres of water and reached a total depth of 4,085 metres.

The Afina-1 well was drilled between the Banda find, which was announced in 2011 by Kosmos Energy, and Eni’s Sankofa field, in the Offshore Cape Three Points (OCTP) licence.

Undiscovered potential on the WCTP Block 2 is estimated by Springfield at more than 3 billion barrels of oil and gas, across various reservoir units.

Springfield E&P is the first Ghanaian, and first African, company to drill in the deepwater and find hydrocarbons, it said. The company has an 84% stake in the WCTP Block 2, while the remainder is held by Ghana National Petroleum Corp. (GNPC) and GNPC’s exploration unit, EXPLORCO.

GNPC’s CEO KK Sarpong welcomed the Afina-1 news and the “all-Ghanaian partnership. This achievement fits into GNPC’s strategic pillars of: ‘replacing and growing reserves’ as well as ‘enhancing sustainability through local content development.’”

Springfield E&P was set up in 2008 and began hunting for a block in 2012, winning the WCTP Block 2 in 2016.

Namibia Set to Further Reform Policies to Curb White Farm Ownership, in South Africa’s Footsteps

Click here to view original web page at sputniknews.com

The previously established scheme involves handing over lands to the state, which was to distribute it evenly between those in need. White farmers were to be allotted “fair compensations”, but the plan didn’t work out, raising concerns about the possibility of forceful expropriation.

It appears that Namibia’s “willing-buyer, willing-seller” approach intended to distribute land to “previously disadvantaged Namibians” yielded no results, prompting President Hage Geingob to call for a more clear-cut and decisive approach.

Geingob has since demanded a constitutional amendment that would allow for the forceful expropriation of white-owned farms, which account for nearly 70 percent of the total number found in the southwest African country. Meanwhile, white Namibians, who are mostly descended from former colonists from Germany and South Africa, make up six percent of the overall population.

The expropriation was designed to come with “fair compensation” to the previous white owners – something that revives memories of analogous land seizures in Zimbabwe in 2003. Namibia adopted a “willing-buyer, willing-seller” approach to land reform after independence from South Africa in 1990. Farmers wishing to sell their business must first offer it to the state, which parcels it into smaller plots and redistributes to “previously disadvantaged Namibians”, as pledged by Geingob, who has been re-elected for another five year term.

However, there is at least one apparent setback to the approach: a thriving farm, purchased by the government and then handed over to someone else, will not necessarily be looked after well.

One land owner, cited by AFP, Helmut Halenke of Bavarian descent, like many others, expressed concern that land sales and purchases could cripple agricultural production unless “done in the right way”. “You cannot take a man from under a tree… and put him on a farm”, said Halenke. “You must enable people first”, he remarked, adding, though, that the cash-strapped government is highly unlikely to buy out the white farmers’ land plots. Meanwhile, neighbouring South Africa, which has a very similar distribution of land between its citizens, has been increasingly witnessing quite a few violent episodes involving racial rhetoric with regard to land proprietorship.

Earlier this year, a number of local media outlets reported a spate of attacks on white farmers in South Africa that have left several gravely injured and a large number of people dead . The issue has long been an apple of discord in the nation, as the number of attacks is said to have risen lately from between 100 and 200 in 2012 to over 400 in 2018, per The Daily Caller.

IREX International Robot Exhibition 2019

Click here to view original web page at www.japanistry.com

Exhibition held every other year to showcase the latest in robotic technology. Most of the robots on display are aimed at industry (rather than consumers), but the exhibition is nevertheless popular among those with a general interest in technology. 2017 saw over 600 companies put on 2,700 booths for the 130,000 visitors that came during the four days.

Realtime Robotics extends technology relationship with Mitsubishi Electric

Click here to view original web page at roboticsandautomationnews.com

Realtime Robotics , a developer of responsive motion planning software for industrial robots and autonomous vehicles, is expanding its partnership with Mitsubishi Electric .

The company is to develop a “custom integrated solution” that pairs Realtime Robotics’ smart motion planning technology with Mitsubishi Electric’s industrial and collaborative robot product lines.

The intelligent robots will be on display at iREX later this month and there will be a series of demonstrations showcasing the motion-planning technology in action.

Despite the growing demand for automation, multi-robot work cells continue to require complicated, time-consuming, and costly programming, which prohibits the automation of new tasks.

The custom Mitsubishi Electric seamless stackable solution significantly reduces work cell development time and costs while reducing cycle time with interlock-free, collision-free autonomous planning.

The joint solution delivers the productivity and efficiency gains that increased automation has promised but failed to deliver as yet.

Incorporation of Realtime’s technology enables industrial robots to work safely in dynamic, unstructured environments, allowing the robots to evaluate millions of alternative motion paths to avoid a collision and choose the optimal route before making a move, all in milliseconds.

The integrated robots will be demonstrated at Mitsubishi Electric’s booth (S1-03) at iREX in Tokyo (December 18-21) and will be commercially available in 2020.

Peter Howard, CEO, Realtime Robotics, says: “Our shared vision with Mitsubishi Electric is to help robots realize their potential in industrial settings. We are excited to unveil our motion planning technology coupled with Mitsubishi Electric’s robots at iREX, removing many of the boundaries to greater robotic automation.”

Satoshi Takeda, senior deputy general manager of Nagoya Works, Mitsubishi Electric, says: “Smart manufacturing requires productive and safe robotic systems. With Realtime’s innovative motion planning technology, together, we will be able to transform industrial automation.”

Built Robotics raises $33M for its self-driving construction equipment

Click here to view original web page at techcrunch.com

Built Robotics, a company aiming to make construction equipment autonomous, is announcing a $33 million Series B round this morning.

With the construction industry facing a global labor shortage , Built’s aim is to allow one equipment operator to oversee a fleet of vehicles working autonomously in parallel, hopping in the cab only for tasks the machine can’t handle.

Rather than building its own vehicles, Built focuses on converting the popular construction equipment that’s already out there. They sell a kit that straps to the top of things like excavators, bulldozers and skid steers, taking tech like lidar, GPS and Wi-Fi and meshing them into the machine’s innards to give it autonomous smarts. They sell the conversion boxes to other companies, help them get installed, then charge a usage fee whenever the machines are in autonomous mode.

No one wants a 20-ton piece of machinery blasting around a construction site without a care for those around it, so the autonomous machines try to keep a constant eye on their surroundings. As I wrote back in April : Cameras on and around the vehicles are constantly checking for anyone who might stray too close. If something goes wrong and the machine starts to tip too much, or if on-board sensors detect that something is in the way underground? Power gets cut. And there’s a big red emergency stop button on the back of each machine (and a wireless button meant to stay on the operator’s desk) for good measure. We also took a look at some of Built’s gear a few months back: The round is lead by Next47 (the investment arm of the European mega company Siemens), along with Building Ventures and previous investors Founders Fund, Presidio Ventures, Lemnos and NEA. As part of the deal, Next47’s T.J. Rylander will be joining Built’s board of directors.

The company had previously disclosed a $15 million Series A it raised in 2017, bringing its total funding up to $48 million. Built co-founder Noah Ready-Campbell tells me that the company has roughly doubled in headcount over the past few months, with the team now sitting at roughly 40 people.

How Robots Are Changing the Construction Industry

A robot called MULE, from Construction Robotics, lifts heavy concrete blocks. Along the banks of Lake Michigan, 20 masons lay bricks for a huge dorm, as big as three football fields, at the Naval Station Great Lakes in Illinois. Compared with those in years past, these workers are doing far less laying and “buttering” and, instead, are focused on quality and on cleaning up mortar joints.

A robot named SAM handles the real grunt work.

SAM, a clawlike metal arm extending from a cage, moves back and forth along the walls, buttering and layering a brick every eight to 12 seconds. Nearby, another robot called MULE uses a burly 12-foot arm to lift heavy cement blocks for workers, who then guide them into place.

Neither bot takes sick days or gets sore muscles, and both can work around the clock. “It’s all about reliability and certainty that the job will get done,” says Tyler Shawcross, senior project manager at Clark Construction, the general contracting giant co-overseeing the Navy project.

These days, reliability is a big issue in the construction industry, responsible for nearly $10 trillion in global spending annually. The vast majority of large construction projects go over budget and take 20% longer than expected, according to consulting firm McKinsey.

The problem is partly owing to a labor shortage. In August, 7.1 million construction jobs went unfilled, and 80% of construction companies say they struggle to recruit and hire people, according to a survey by software firm Autodesk and Associated General Contractors of America.

Construction work—whether building bridges, roads, or homes—is dirty, physical, and dangerous. The sector is among the leaders in workplace fatalities, with 965 job-site deaths in 2017, according to the U.S. Bureau of Labor Statistics.

Investors think technology can fix some of the construction industry’s downsides. Last year they pumped $3.1 billion into tech startups focused on everything from construction-scheduling software to factories that churn out prefab housing to robots like SAM.

“In the last three years, there’s been a big transformation,” says Scott Peters, cofounder of Construction Robotics, based in Victor, N.Y., and maker of the SAM and MULE robots. “Most people understand change is needed.”

But with low profit margins, high risk, and tight timelines, the construction industry is notoriously cautious. Adding new technology requires contractors to rethink how they do their work, and that adds to the cost and risk.

“If there’s an accident, who is at fault?” says Jose Luis Blanco, a partner at McKinsey. “No one wants to be the first one when it goes south.”

The push to use robots is, of course, still in its early days. Although the technology exists for certain kinds of construction work, it isn’t there for electrical work and carpentry, which require more finesse. Price is also a major stumbling block. The robots sold by Construction Robotics, for example, cost $75,000 to $500,000.

Even if construction executives favor new technologies, getting everyone else on board, from foremen to frontline workers, can be difficult, says Peters. Masons, for instance, had some misgivings about the SAM bricklaying robot when it was unveiled at a trade show in 2015 because some of them feared losing their jobs. “You got some people who were super excited and other people who were scared to death,” Peters says.

MULE has had a warmer welcome from the International Union of Bricklayers and Allied Craftworkers. Its robotic arm can quickly lift tools, stones, and concrete panels of up to 135 pounds, eliminating physical strain on human workers.

“SAM is a little bit different,” says Bob Arnold, the national director of the union’s arm responsible for job training, “because they feel that it’s replacing them, and, in a way, it could.”

Despite those mixed feelings, the union started training its members to use the machines. Over the past three years, Construction Robotics has deployed its technology on 165 job sites in three countries.

Other companies are also trying to gain traction with their construction-focused robots. Hadrian X, by FBR in Australia, builds walls for a complete home in a single day using bricks that are 12 times as large as traditional ones. Meanwhile, Toggle, in New York, uses industrial robots to fabricate and assemble rebar cages.

A host of Bay Area startups are also getting in on the act. Doxel builds autonomous robots and drones with 3D vision and artificial intelligence that roll around and fly over job sites, inspecting how much plumbing work has been done and whether it was done correctly. Ekso Bionics makes robotic vests that support a worker’s arms for jobs like drilling or installing piping overhead. It also sells a robotic arm that makes it easier for workers to use heavy tools, reducing fatigue and injury. And Dusty Robotics makes small autonomous bots that roll around construction sites and mark lines on concrete floors that indicate the location of walls and infrastructure, based on construction documents.

Few companies are trying anything as ambitious as San Francisco startup Built Robotics. It sells autonomous technology for bulldozers and other heavy equipment. The tech can enable a Caterpillar tractor, among others, to move dirt and lift pallets of wood—all without anyone in the cab. Technology from Built Robotics enables heavy vehicles like backhoes to drive themselves—and, theoretically, to get better at it over time. The “brains”—a combination of sensors, intelligence, and cameras—are affixed atop the vehicle’s cab inside what looks like a car luggage carrier. Software engineers must work with on-site contractors, who pay a monthly fee for the technology, to program the autonomous guidance system for specific jobs.

Geofences—which tell the computer the physical boundaries of a job site—and remote kill buttons keep the vehicles from going awry. Over time, with the help of machine learning that analyzes their work, the vehicles are supposed to get smarter.

Mortenson, a large contracting firm, is using Built’s autonomous technology on tractors that move dirt and build roads at five wind farms in rural Texas, Kansas, and eastern Colorado. Covering 100 square miles or more, the wind farms are ideal places for testing such new technology, says Eric Sellman, a Mortenson vice president.

“The robots keep getting better and better, and smarter and faster,” he says.

This technology, Sellman says, makes job sites safer by letting construction crews stay clear of danger while they focus on other tasks, such as planning. Workers are also assigned to oversee the bulldozers, often monitoring several machines at once, and then verifying whether they’ve done a good job.

Sellman hopes that robots will ultimately become a recruiting tool, encouraging more young people to pursue careers in construction.

“There isn’t any rule book yet on how robots and people will work together,” Sellman says. “But we know we need to start teaching our people the skills now to prepare for a future where we work differently and work smarter.” Robots Cement Their Place in Construction

Startups are working to automate different jobs within the building industry. Here are a few examples. Courtesy of Fastbrick Robotics FBR

This company’s Hadrian X robot has a mechanical arm mounted on a truck that builds walls faster than humans, with bricks that are 12 times as big as traditional ones. Courtesy of Ekso Bionics EkSo Bionics

Its vest supports workers’ arms and backs to provide superhero strength, reducing fatigue and injury. A separate robotic arm makes heavy tools seem weightless. Courtesy of Built Robotics Built Robotics

A system of cameras, GPS, sensors, and A.I. turns bulldozers and other heavy equipment into autonomous vehicles that can dig without human operators.

A version of this article appears in the November 2019 issue of Fortune with the headline “Bots Start Building.” More must-read stories from Fortune :

—Why the Midwest is a hotbed for innovation

— Nintendo’s Switch Lite helps capture new audiences—women and families

—A new Motorola Razr —and its folding screen—could bring phone design back to the future

—Most executives fear their companies will fail if they don’t adopt A.I.

—How giving thinkers and tinkerers room to experiment builds a better company Catch up with Data Sheet , Fortune’s daily digest on the business of tech.

Community-First Opportunity Zones: How Everyone Can Win

The opportunity zone (OZ) program is designed to funnel private investment into distressed communities across the nation, creating housing and essential infrastructure and spurring economic revitalization. Program proponents call it a once-in-a-generation opportunity for local communities in need and a creative way for private sector investors to fund improvements. Skeptics argue the program is a tax break for the wealthy and doesn’t address fundamental issues facing the low-income areas it was designed to help. These cynics claim the program will cause gentrification and further displacement of low-income residents and minorities. Achieving the positive intent of the legislation will be addressed in this first installment of a column that explores how a local focus can revitalize low-income communities.

To start, the Tax Cuts and Jobs Act of 2017 established the OZ program with broad bipartisan congressional support to create long-term positive change via capital gains tax incentives for those who reinvest capital gains in qualified opportunity zone funds (QOZF). The media has focused on billionaires lobbying to create new OZs where they own property and large fund managers claiming that the program isn’t attractive enough to solicit investment.

This doesn’t paint a clear picture of the whole story . Real estate development is an integral part of any healthy city. Issues like gentrification and displacement always have to be taken into account regardless of where the development occurs. Working in coordination with local residents, community leaders, city staff and elected officials to address issues like these can generate the positive economic impact the OZ program was designed to create.

In order to realize this positive economic impact, we must understand what we are trying to achieve in the communities served by QOZFs. I believe that impact studies will be essential to proving the OZ program’s success. Others, like the U.S. Impact Investing Alliance and the Beeck Center, are in agreement and have developed a framework to help OZ stakeholders measure, manage and deploy capital — benefiting both investors and the community.

As a local-first OZ fund, my company’s mission is to deliver positive outcomes for investors and positive impact on the community. I’ve seen firsthand in our area of San Jose how local-focused investment can benefit both parties involved.

PROMOTED

The Win-Win End Game

I believe the ultimate objective should be executing OZ development that results in a win for investors and communities, giving each the type and scale of projects they desire. For example, Northern California is experiencing a housing crisis driven by 30 years of unprecedented job growth. Skyrocketing housing prices have forced low-income residents to seek affordable housing outside job centers, creating urban sprawl and clogging freeways with commuter traffic. The OZ program incentivizes private investment in new housing development in places where housing is desperately needed. New homes will help balance supply and demand to better equalize prices, making more affordable local housing more attainable.

Early on, potential QOZF investors often equated confusing program details to increased risk, and investment dramatically slowed. It took four months for the IRS to issue important clarifying guidance. Then potential QOZF managers had to get their heads around the clarified legislation, determine that changes were sufficient to create successful business plans and structure funds around those plans. A slower-than-expected rollout of the OZ program has delayed funds, and, as a result, the positive impacts of the program are yet to be seen.

In most cases, it will be several years before new buildings are constructed and tangible impacts are apparent, and in that time I expect to see best practices emerge — from measurement guidelines and impact studies to the unveiling of trend-setting developments. Yes, opportunity zones are new to investors and communities alike, but I believe exciting times are ahead for those who decide to play.

Community-First Development

For the OZ program to reach its full potential, everything should point back to the community. Local-focused developers and funds that benefit the community, as well as investors, are critical because positive local economic impact requires active fund involvement and participation within the OZ. A fund model spreading hundreds of millions of dollars across multiple, disparate OZs and lacking critical connections within the community simply won’t cut it. Development must meet the expectations and needs of the community and promise investor returns to fund well-conceived renovations and ground-up developments at scale. Bottom line: Both communities and investors must be rewarded.

Local-focused developers and fund managers have the boots-on-the-ground experience and connections to engage important constituents, devise the right strategies and — paramount — quarterback projects from inception to completion. A community-first pedigree means being part of the fabric of the community and knowing how to listen to important leaders and constituents who are next-door neighbors: residents, business groups, community advocates, nonprofits, city planners and local elected officials. It requires walking the neighborhoods, meeting the residents and acknowledging what can be done to bring the city together. This will give OZ investors a way to impact the community and realize financial benefits.

The Tightrope

This balancing act involves weighing competing priorities. What does the community want to see? What will the planning department want to see? What is going to revitalize neighborhoods and not cause displacement and gentrification? What do local politicians need to deliver? What would attract investors to fund projects? Understanding the tradeoffs and finding that balance between needs, wants and returns is key to uncovering transformative projects that are the right fit, which will be different for each community .

Addressing long-term decline and generations of underinvestment is complicated. Opportunity zones present an innovative solution involving the private sector to rebuild communities. Rigorous accountability and reporting are needed to measure impact, while an established framework is essential to program success. Developer-led funds with a community-first focus play a critical role in building the win-win outcome for investors and communities in need.

The buyers and sellers of Khorgos, a special trade zone on the Kazakhstan-China border

An unusual shopping tour. The overnight bus arrived at the border of Kazakhstan and China at about 4am. The 20 passengers on the 50-seat bus were still sleeping. There was three hours to wait before the border checkpoint would open.

The passengers had come from all over Kazakhstan to visit a visa-free duty-free shopping zone inside Khorgos, a town that spans the Kazakhstan-China border.

The two countries conceived the cross-border development in 2011 to transform Khorgos into a major trade and transport hub. It sits on the New Silk Road, a section of China’s Belt and Road Initiative, creating an over-land trade route linking China to European sea ports through Central Asia. Eight years in, the town hasn’t become a global-trade nexus. Nonetheless this 5.3-square-kilometer (2-square-mile) shopping zone, formally called the Khorgos International Center of Cross-Border Cooperation (ICBC), has lured entrepreneurs hoping to get rich and shoppers trying to get a bargain.

Part inside Xinjiang Uyghur Autonomous Region of China and part inside Kazakhstan, the ICBC is a neutral territory. Visas aren’t required for Kazakhs to go to the Chinese side, or Chinese to the Kazakh side. Most shoppers, however, come from Kazakhstan and nearby Central Asian countries to buy Chinese goods: Five multi-story shopping complexes housing over 2,000 shops have been built on the Chinese side. The single shopping mall on the Kazakh side is still under construction.

Shoppers typically travel long distances on tour buses to spend the day traversing the Chinese malls. The zone estimates that 4,000-5,000 Kazakhs visit the shopping area on a weekend day. A fur-coat store owner estimated to Quartz that on a good day, there’d be around 7,000-8,000 customers.

Quartz talked to some shoppers and business owners to learn why they came here, and what they’ve been trading. The bus passengers wait for the customs checkpoint at Khorgos to open. The shoppers in Khorgos

Shoppers from the tour buses get to the malls after the Kazakh customs building opens at 7 am, and leave before it closes at 7 pm. Valerka Vojutulevitsh bought an electric scooter. Valerka is a 22-year-old hotel receptionist from Almaty, the most populous city in Kazakstan. An overnight bus brought her, her mom, and her aunt to Khorgos. They departed around 11 pm from Almaty, spent four hours on a recently-built four-lane expressway to reach the border, and waited three hours in the parking lot for the customs checkpoint to open at 7am.

This was Valerka’s first trip to the trade zone. She bought an electric scooter for 84,000 tenge ($215). Her mother said that the same scooter would be priced over 240,000 tenge ($615) in shops in Almaty. She also bought Elizabeth Arden Green Tea Scent Spray for the equivalent of $30. That’s about the same price the company sells it for in its US store before taxes. Anna Shalygin and Alexander Shalygin On the same bus with Valerka were Anna and Alexander . They were on a buying trip for their cosmetics store in Karagandy, Kazakhstan. They flew to Almaty to purchase supplies and continued to Khorgos. They came to meet their supplier of Chinese medicines and also bought clothes and linens for their family. In this store, Baket bought false eye lashes and souvenirs to bring back home. Baket , a makeup artist living in Nur-Sultan, the capital of Kazakhstan, came to Khorgos for a two-day shopping trip. Baket was born in China and is ethnically Kazakh. She bought socks, facial masks, flip flops, false eye lashes and some souvenirs for her friends. She said that everything back home was much more expensive than in Khorgos. Aigul Orozbayeva with her daughter, and the electric wheelchair they bought. Aigul is a social worker at a special-needs facility in Bishkek, the capital of Kyrgyzstan. She took an eight-hour bus with her daughter and a facility resident from Bishkek to Khorgos. They came to test and buy electric wheelchairs for the facility. Electric wheelchairs sell for 130,000 tenge ($330) in Khorgos. Aigul said that’s about the half the price of those in Bishkek. She comes to the trade zone about three times a year to buy things for the facility. Saule Khasenovna and Balnur Isaevna Saule and Balnur are school teachers and colleagues from Shymkent, the third-most populous city in Kazakhstan. They came with a tour bus for a one-day trip. Khasenovna spent 155,000 tenge ($400) for a fur coat, about one month of her salary.

The border officials keep records of visitors to the ICBC. The Eurasian Economic Union, of which Kazakhstan is a member, fears an influx of cheap Chinese goods. The Kazakh government prevents shoppers from entering the Khorgos ICBC more than once a month. It also limits purchases to 25 kg of goods worth less than €500. The limit was lowered from 50 kg worth less than €1,500 in January.

There’s a size limit too. Purchased items get boxed together and tightly wrapped up before being loaded onto the bus. To take advantage of duty-free benefits, some family-business operators have their Chinese supplier ship goods to the zone, and then bring family members there to increase the amount of goods they can carry back home duty free; others pay workers inside ICBC to skirt the limits . The shop owners of Khorgos

King Kong Fur Center in Khorgos Stores operate around the hours of the border gate. Seven days a week, stores open when the border does, and close before the border gates are locked. The Chinese side of the zone follows Beijing time; it’s two hours ahead of the Kazakh side. Wenyuan Wang has fur-coat stores in Beijing, Moscow, and Khorgos. Fur is popular with Kazakhs, and coats are cheaply sold by Chinese merchants at Khorgos.

“All shops here are owned by Chinese traders from all over the place,” said Wenyuan , the owner of a fur coat store in King Kong Fur Center, a five-story shopping mall designated to sell fur coats.

Wenyuan is from Hebei, a province next to Beijing, known for manufacturing and exporting fur clothes. He sources supplies from there and Europe. At 33 years old, he owns fur-coat stores in Beijing, Moscow, and Khorgos. He said the depreciation of yuan has lowered his profits this year.

Wenyuan, like many shop owners on the Chinese side, doesn’t speak Russian, but the three shopkeepers in his store do. Together they speak Russian, Kazakh, and Mandarin. Changhe Zhou folds a blanket at his linen shop in Khorgos ICBC. Changhe ‘s linen and blanket store in ICBC opened six months ago. Changhe is from Shaoxing, a city in eastern China. He used to supply Khorgos linen sellers, but decided to operate his own shop when he realized that he could make more money by selling directly to consumers. He has one Chinese employee and has found success selling colorful, soft blankets with cartoon patterns for 2500 tenge ($6) each. He said that 30% of his business is retail, and 70% is wholesale. Xianpeng Gao owns a shoe store in Khorgos. He wears a badge that says “security personnel.” Xianpeng operates a leather shoe store on the first floor of one of the shopping malls. He came to Khorgos in 2015 from China’s northeast province of Jilin and can speak Russian. Xianpeng used to export goods through the ports in Northeast China to Russia and Europe. He moved his business to Khorgos when he saw a better opportunity to profit. Ziyuan Wang operates her store in Khorgos as an outlet of her shop in Urumqi. Ziyuan and her husband Yuan own a shop on the fifth floor of the Zhong Ke shopping mall. They sell medical equipment, household containers, Chinese teas, and even diapers. Most items don’t have price tags. On the day of Quartz’s visit, Ziyuan and Yuan’s interpreter was late. Ziyuan communicated prices by displaying numbers on a handheld calculator. The Khorgos store is an outlet of the couple’s first store in Urumqi, Xinjiang, nine hours’ drive away from Khorgos. Beka sells tires, but weight-limit rules at the border make business harder. Beka ’s tire shop sits outside of the shopping malls. He’s ethnically Kazakh from Yili, Xinjiang. The heavy weight of tires is a huge problem for Beka because of the 25 kg per person weight quota enacted in January. “You can only carry two tires out at once,” said Beka. Items that are shipped out of the zone loose their duty-free treatment. Combined with freight fees, that can more than double the cost of the typical 195 yuan ($30) tire. The shoppers stuff their purchases onto the shuttle bus, preparing to leave Khorgos ICBC. On the day Quartz was in Khorgos, large anti-Chinese-investment protests in Almaty and Nur-Sultan led to dozens of arrests . China is Kazakhstan’s second largest trading partner. The protesters said that Chinese infrastructure projects took jobs away from the locals and resulted in high national debt. They also protested against China’s mass imprisonment of Muslims in Xinjiang, many of whom are ethnically Kazakh.

The shoppers Quartz talked to were unfamiliar with the protests. But businesses and sellers in Khorgos knew. They said that certain topics were not allowed to be talked about because Khorgos was inside Xinjiang, a region under the highest level of Chinese national surveillance. It’s home of the largest Muslim community in China. There were security checks at the entrance of each shopping mall. The police officers inside the malls wore jackets emblazoned with “anti-riot” in Chinese characters. Some shop owners and restaurant staff can be spotted wearing red badges with the words for “security personnel” written on them. One shop owner told Quartz the badge wasn’t very hard to get.

Despite all this, shoppers come everyday before dawn and leave before dusk. For Khorgos, that’s business as usual.

Meet the American billionaire ‘king’ of Ghana

Michael V. Roberts Billionaire Michael V. Roberts who has been turning the business world on its head is now the economic king of Ada; eastern part of the Greater Accra Region in Ghana.

This information was shared on Instagram by American author Dr Boyce Watkins who together with his son are now part of the Diaspora Royal Family in Ada.

According to the Instagram post, Robert’s coronation comes on today December 12.

Who is Michael V. Roberts?

Entrepreneur Michael Victor Roberts, Sr. was born on October 24, 1948, in St. Louis, Missouri to Delores Talley Roberts and Victor Roberts.

He began his first business selling dashikis and other African merchandise to area bookstores. Roberts studied law at St. Louis University School of Law, and in 1974, earned his J.D. degree and began Roberts-Roberts and Associates, a business and construction management firm headquartered in St. Louis.

In 1976, Roberts worked as St. Louis campaign manager for Jimmy Carter, and after Carter’s election as U.S.

In 1981, Roberts and his brother began Roberts Broadcasting. After establishing WRBU-TV in St. Louis, the Roberts Brothers would build eleven more television stations across the country.

In 1999, the Roberts Brothers opened the first Sprint PCS-affiliated wireless store in Jefferson City, Missouri. It was the only PCS-affiliated company owned by African Americans. The Roberts Companies include a $460 million thirty-four-company organization, with an aviation division, a gated Bahamas community and other real estate developments. Roberts serves as chairman of the board, while his brother Steven serves as president.

Year of Return, Ghana 2019

The Ghana government has thrown invites to black people the world over as part of the “Year of Return, Ghana 2019”.

The initiative involves a year-long series of activities. These include visits to heritage sites, healing ceremonies, theatre and musical performances, lectures, investment forums and relocation conferences. The aim is to promote Ghana as a tourist destination and investment opportunity.

This year marks the 400-year anniversary of the first enslaved Africans’ arrival in Jamestown in the US. The Year of Return represents an effort to unite Africans on the continent with their brothers and sisters in the diaspora”.

In support, Ghana’s President Nana Akufo-Addo said “we know of the extraordinary achievements and contributions (Africans in the diaspora) made to the lives of the Americans, and it is important that this symbolic year – 400 years later – we commemorate their existence and their sacrifices”.

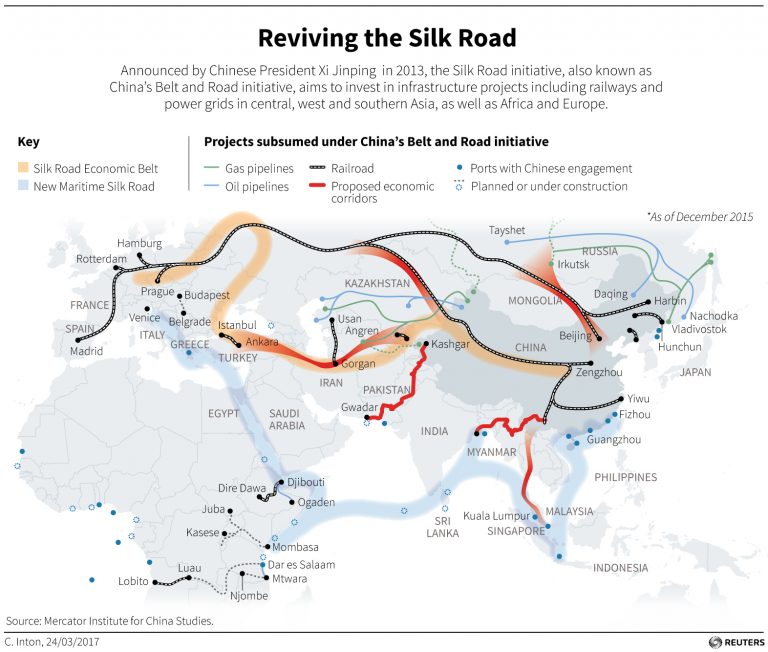

There is a Black Mecca forming on China’s 20 Trillion Dollar New Silk Road

Nur Sultan, Kazakhstan, Central Asia

Along the hills, in the mountains of the caucus, stretching from the historic city of Urumqi all the way down to the historical roads built by the Romans, there is a road that once was the absolute center of all trade in the world. The Silk Road as they called it, is the instrument that introduced China to Europe, Africa to China and blended the world’s nations into the outcome for which we see today.

The abandonment of that road signaled the growth of the European empires, the rise of colonialism, the establishment of the United States and what we know today and have accepted as developed nations. However, China, along with a majority of the previous colonized nations, have revitalize these historical centers of power and trade to re-establish themselves in a new era of modern technology and industrialization. In the center of this once historical and now monumental set of roads is something that was never there before, a town that is ready to be a haven for African-American entrepreneurs.

More than two dozen African American businessmen have visited and registered their businesses in Kazakhstan in the last five months. Kazakhstan is a country that is little known to most people in the United States. In most circles, amongst African Americans, not only is the name unknown but most can’t even pronounce it. So how is it that it is now coming to be known as a home for African American Businesses in Eurasia? In order to understand this, you first have to understand what the New Silk Road is and the significance of Kazakhstan in the future of the world

In 2013 President Xi Jinping traveled to Kazakhstan Nazarbayev University to announce the launch of what would become the project of the century. Over 20 trillion dollars invested in thousands of mega infrastructure projects would be launched by a single announcement in Astana, Kazakhstan. From New roads to modern highways, power stations to the largest fiber optic networks on the planet, from 5G networks to huge hydroelectric dams, some of the largest ports ever built in history including those on land as well as those at sea and some of the greatest construction projects known to date are included in what would be called the New Silk Road.

Since its inception the project has taken on a couple of different names. One belt one road and the Belt Road Initiative have all been the titles given to this enormous project that is the cause of Chinese businessman appearing in Africa throughout the other parts of Asia and throughout Europe. This single initiative is responsible for the rapid growth of almost every previously colonized nation in the world. None however are more significant than Kazakhstan

Why would the leader of one of the most powerful Nations on the planet Earth choose to start the project of the century inside of a country that most of us barely know anything about? The answer is simple, Kazakhstan is China’s greatest path out to the world from the West of China. From any map if you move your finger along a straight line to the West you will see the greatest amount of China’s western border against Kazakhstan.

To add to the significance of its location, Kazakhstan is the only nation where American, Chinese and Russian interest collide in a peaceful relationship with the nation’s leadership. Strategically, a designated autonomous business region known as the AIFC or the Astana International Finance Center, has been developed to provide the special circumstances needed to grow the region into a hub for modern international business.

It is in that hub that the first business center dedicated to US minorities has been established. Qosil, Ltd lays at the very heart of the New Silk Road. For the first time in history a special business center and autonomous business district is dedicated to servicing the needs of African American businessmen who are building a home for their interest in Eurasia.

“we share a common history of surviving the hardships of forced labor and coming out as winners” says one Kazakh business man. “You are our brothers and we we ready to stand with you in business and as neighbors.”

Qosil, Ltd offers a guided one stop shop to all of the services of the AIFC. African American businessmen are chosen by the group to visit Kazakhstan and in the course of one day, they provide everything they need to register their business, secure housing, secure office space, start their first deals, hire their first staff and receive a five year visa that can extend to forty years.

The AIFC provides the businessmen tax exemption for themselves and their businesses for 45 years, a legal sandbox to waive laws for innovative businesses, a British based legal center, international arbitration court, office space in one of the most advanced central and amazing structures in Asia, startup incubators and on-site regulators and courts in Central Asia’s premier financial center.

“Eurasia is a seller’s market. We have to shed the idea that Asia is only a place to go to buy things to take to the US. The true opportunity is to make a second home in Asia and create businesses to sell into Asia, Russian and European markets. Kazakhstan is the absolute best place for us to make this happen.” Managing Director of Qosil, Ltd.

Colonialisms last battle – the complete extinction of handmade goods!

The most sustainable home in Africa. At the sound of it it was an amazing accomplishment. But there was something a little hollow about it. Although we had taken time to work with the students and create a beautiful home that was built from sustainable materials. There was a part of it that just wasn’t right. The contributions of the students from Cadi Ayad University, a portion of the team that was supported by Freedom builders in Atlanta, to develop what later became the winning home for the US Department of energy solar decathlon in Africa, brought something unexpected, Ikea!

When we set out to build the home, we insisted on using the same materials that we were creating in the United States to give power back to our people to fulfill the most simple and basic rights that any human being should have, the right to proper shelter. As a way to lean on the expertise of others on the team, the interior decorations were left to the Moroccan students. The thought was that a place like Morocco, with the historical city of Fez and the bustling economy of handmade goods in Marrakesh, would produce a set of individuals that would dig deep into the heritage of handmade crafts and provide amazing artifacts for the home. That was very far from the case. As Moroccans are still heavily bound by the curse of colonialism.

As one of the first major trading cities in northwestern Africa, Fez Morocco has stayed exactly as it was 800 years ago. The first degree granting University in the entire world, one of the oldest leather cooperatives on the planet, over 10 miles of winding streets laced on either side with artisans making handmade crafts in a manner that would have been prevalent before a single ship ever set from the shores of Europe to colonize the world. This is the setting that we expected the students of Morocco to venture into in order to find beautiful handmade and hand-cut chandeliers, handmade leather for couches and pillows, handmade wood work from the master carvers for our cabinets and our shelves. Instead the very first thought that came to the mind of the young Moroccan was the fill the house with furniture from the new Ikea store that has now been open in Morocco for the last 3 years. A decision that was seconded multiple times from all of their fellow students and professors.

But, it’s not like this shouldn’t be expected. A, in the United States we have seen a resurgence of the demand for handmade goods, what is known as the developing world, still maintains a deep desire for mass-produced products. Even though there is an abundance of Craftsman still available in their countries. To any American it would seem no less than Ludacris that a person who can walk down the street and have a piece of clothing custom made for less than we could by a cheap knock off, would then choose the knock off. Moroccans as well as the North African, sub-Saharan African, southern African, middle Eastern, Eastern European, and Central Asian neighbors see the modern styles of mass-produced products as a sign of influence and the symbol that they have arrived at a higher class and standing, not only in their society, but in the World at Large. And the thought of buying handmade goods is seen as an experience that should be limited to the poorest people in their society.

This was an intentional outcome of colonialism. As colonialism made itself to the world it also attached its perceptions and the maturity path of Europe to every society on Earth. There was a time when Europeans valued handmade goods so much that the kings and queens of the time mandated that the best artisans govern the production of all goods in their countries. A system that became known as The guild system insisted that all artisans become apprentice to approved guild Craftsman. The guild system also insured that there would be no product on the open market that had not been made buy a local Craftsman. But there was a loophole. The Islamic and the Mongol empires had produce excellent Craftsman that brought products and innovations to the world that Europe could not deny. As a result, products brought along the silk road we’re allowed to be sold by merchants in the markets of Europe.

Unable manufacture products inside of Western Europe without the explicit permission of the guild Craftsman, who acted no less than that of an organized Mafia, merchants who did not want to traverse the dangers of the silk road decided to find an innovative method to produce products within their own countries. This gave birth to what was known as The cottage system or the putting out system. In this system a merchant would go from Village to Village getting small parts of a production put together by people who were capable of doing a single task in the construction of a good. In the example of a piece of clothing, a merchant would go first and buy the wool from sheep farmers. Then, he would deliver the wool to an entirely different village, where someone would spin the wool into yarn. He would then pick up the yarn and go to another village where someone could make fabric. And then yet several other villages until the product was finished and he could sell it at the market.

Legally, this method of producing goods fell within the guidelines of imported goods and allowed the merchant to bypass the guild system and remove himself from the control of the guild Mafia. However, it soon became a daunting task to traverse through the multiple villages in order to put together products. So merchants got a little clever. They decided to build centralized warehouses. Then they instructed the same Village goers to bring their products to the centralized warehouse and pick up their goods from the centralized warehouse for producing to the next stage. This was the beginning of industrialization.

Being ever more greedy, merchants decided that it was better for the villagers to move around the warehouse and then come and conduct their portion of the construction of the products within the warehouse. This became the first factory in Europe. It did not go unnoticed by the leadership of the countries that this system existed. However, being an efficient system, the merchants gain power over the guild Craftsman. The next phase of their development galvanized in the 1600’s. This would be the century that the Islamic empire would lose its hold on Spain and Portugal as Queen Isabella and King Ferdinand worked with Rodrigo Borgia, also known as Pope John II, to instate a system of international colonialism and mass slavery.

But unknown to many people, this slavery’s function was to feed what was known as the mercantile system. The mercantile system had evolved out of the advancements in the cottage system. It held that merchants could go abroad to retrieve raw goods but they could not sell anything in Europe or maintain their status in European society, unless the products themselves were assembled in Europe. This simple economic law refrained Europeans from buying handmade goods along the silk road. It encouraged international trade and the development of plantations for raw materials throughout the world. In addition, as it was a system that was implied on the rest of the world with authority of a ruling power over the countries Europeans entered, it also restricted all local persons from being able to make any finish goods from the raw materials they gathered. This was a legal system that encouraged colonialism and built the foundation of slavery.

As Europe and later the United States, became the centers of production the engines of progress also became centered on these spaces. With the invention of the coal powered steam engine in the late 1800s, the world gave way to the merchants dream. What is known in history as the industrial revolution, was the ability to have a machine do the work of a hundred men. Political pressure mounting and the daunting task of maintaining a hold on so many spaces and people, the use of machines in order to produce goods was it gift that every European or American merchant would have told you was from the heavens. In addition, the use of these machines for production would replace not only the production of common handmade goods but also give way to the mass production of things like vehicles and weapons. The merchant was no longer considered a merchant he was considered a manufacturer.

Once manufacturing led to the mass production of weapons it developed some of the largest war machines in history. As an inevitable consequence of the rest of the world not using manufacturing at this scale, World war 1 saw the complete and utter destruction of non modern industrialized society. This meant the fall of the Ottoman empire and, at the time, the reduction of Muslim governed countries to zero.

A leader in manufacturing, Germany rose as a superpower. Challenging the entire world with the idea that the Aryan race was the most Superior set of human beings on the planet. In World war II the industrialized machine pushed 120 battalions of the military into Russia and throughout Eastern Europe. A force that was ten times greater then the Force unleashed on the United States, the UK and allied forces. The move to take Russia gave birth to the iron hand of Stalin. Unknown to many of us in the West, Russia loss almost 70% of their population do to attacks in World war II. Even though Stalin is best known for absolute cruelty to people in Eastern Europe and Central Asia, he became an effective evil. By stopping the onslaught of central Asians and Eastern Europeans by Germans, he himself gathered them as a workforce through his own cruel measures.

Stalin consolidated entire populations to parts of Russia where he could do in five years what the West did in 200 years, build an industrialized superpower. Through the course of World War II, Russia develop more planes vehicles weapons and other goods then their counterparts in the West. This feat is what established Russia as the mega power of the East until modern day. After World war II subsided it was clear the industrial systems of the United States, the UK, Russia, and Japan were the absolute symbols of authority and power.

It only takes one generation for a set of children to forget the suffering of their parents and instead focus on acquiring the symbols and the mechanisms to establish their own self identity and their own concept of power and control. We find ourselves in the set of such generations in the world today.

For the developing world the desire to become industrialized nations runs all the way to the core of what it means to have control and freedom over your life. For the average person in any developed country the idea of going back to handmade goods and encouraging the development of handmade products is not a symbol of craftsmanship or intelligence but yet a symbol of their failure to focus on the things that will ensure that they are people that can be in control of their future.

Many times, African Americans are hard to judge other people in developing worlds. As Booker t Washington said the negro was enslaved by industrialization and therefore will never associate industrialization with freedom. This would mean the outcome of our slavery is in direct contrast to the outcome of the previously colonized world.

Whereas we value handmade goods and we hold high the idea of having a tailor-made suit or custom made leather bag our brethren see it as a symbol of weakness. And for the common man it goes less to understanding the necessity to manufacture your own goods and more into the necessity to simply possess a piece of the modern mass-produced world. It is in that outcome that colonialism finds its greatest victory and is constantly winning its last battle. It is not enough to have symbols of industrialization but yet to be the individuals that own the knowledge of how to create the systems and the means by which to develop goods for ourselves.

New generations born to the under developed world can only see the cream. Seeing what those in the developed world have, partnered with a rush and a desire to have a certain feeling of empowerment in one’s life, the time for handmade goods has passed. This desire is magnified greatly by what has become an instant society. The outcome of which proved to be an absolute victory for the colonizers on the previous colonized populations. Even in their desire to grow powerful they destroy themselves.

In Europe and the United States, the effects of mass production are taking their toll. As a guinea pig to the world on the long-term effects of industrialization, we have begun to realize the dangers of a mass production system. The overall destruction and violation of our food Systems. The harmfulness of the products put on clothing and in the materials used to build our homes, has become something that we are fully aware is harmful to our lives. Therefore, most Americans, white or black, have a desire to hold handmade goods to the highest of value.

In stark contrast, the United Nations division on intangible heritage tracks the loss of culture through the loss of skills used to make handmade goods in developing nations. As young people in developing nations choose to go to universities instead of taking on the skills of their grandfathers, the ability to manufacture their own goods and the necessity to do so is dying. The UNESCO list of intangible heritage says the risk of extinction of handmade goods stretches to almost every single country of the developing world and encompasses more than 2,000 skills. The loss of the culture and the true base of unique empowerment of the developing world it’s nothing short of inevitable.

The light at the end of the tunnel is in us. As members of the diaspora and those displaced most by colonization, African Americans have the opportunity to take the best lessons of the developed world into the underdeveloped countries. By using our expertise and knowledge to share with our brethren it is possible to develop a future where Mass manufacturing meets the quality and the rich culture of handmade goods. This has the possibility to deliver us to a future where we are in power and control of ourselves as well as leaders on the Earth.

Article written collectively buy Hassan Wilson and Faruq Hunter. Hassan Wilson is the general manager for Sayyad lifestyle goods. Sayyad lifestyle goods is a brand that focuses on bringing the best of handmade products from former colonized and former enslaved populations to the hands of those who can take the greatest pride in having products that are made by themselves. Currently Hassan travels the world to discover great artisans and bring their products to international markets. Learn more at http://sayyad.life

Revitalizing Rural Towns by creating Micro Villages using Japanese One Village One Product Principles

Master Designing a small town is a long and on-going process. Here is a current shot of our master design for what we call a OVOP Micro-Village in Freedom Village. We hope to see the first one of this design up and completely functioning in 2020. The methodology behind it is the cornerstone of our efforts and design methodology:

The One Village One Product Micro-Village (Micro OVOP)

In 2017, Faruq Hunter traveled to Oita Japan to analyze the model of the One Village One Product initiative founded by the former governor of the prefecture, Mr. Horimatsu in order to reduce economic decline of the rural towns in Japan. The basic structure of the model is to focus the efforts of a single village on the unique production of a product that is derived from local materials and produced at international standards and to do so in a village that has a high level of design appeal as to attract tourism and provide a high quality of life for the residents of the village.

The OVOP Micro-Village runs on three under lying principles. 1) Self-Reliance and creativity 2)human resource development and 3) thinking locally but acting globally. Freedom Institute develops local groups that take the lead to make unique products from local resources for their own use, the use of other micro-villages and to capture markets external to their locality that are identified and developed by the inventory bank.